27 Jul The Ultimate Guide to Choosing Prescription Safety Glasses

The Ultimate Guide to Choosing Prescription Safety Glasses

Good quality eye protection is used by workers in a variety of occupations and environments to keep their eyes safe. In surveys of annual eye injuries, 90% of them could have been prevented with proper eye protection. Different protection is needed for different hazards.

There are thousands of different types, brands and styles, which make narrowing down and selecting the right pair a little daunting. Having worked with many different providers and researched the options available, OpticalRooms have chosen to offer eye protection and prescription safety glasses from the recognised and specialised eyewear brand name Bolle, UVEX and now the 1st Irish fully certified safety glasses manufacturer Corrpro.

In this article, we will cover the following:

THE HAZARDS

- Mechanical & Physical Risks

- Radiation

- Temperature

- Chemical

- Electric

FRAMES

- Frame markings (Safety Codes)

- Frame Aesthetics

LENS INFORMATION

- Lens Safety Markings

- Lens Materials

- Lens Extras

THE HAZARDS

Assessment of occupational risks involves identifying, assessing and ranking risks in the workplace to implement relevant preventive measures. Following from this, consider the fact that those hazards can change depending on your activity, lighting conditions, location etc.

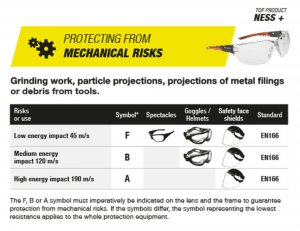

MECHANICAL & PHYSICAL RISKS— Look out for machinery, tools, and objects that can generate flying particles and may create impact hazards.

The mechanical risk mainly occurs during machining operations when sharp-edged particles or those with high kinetic energy are projected.

To protect you against mechanical risks, Bollé Safety has developed a wide range of safety eyewear, including safety glasses, safety goggles and safety face shields.

Practical examples of Mechanical and Physical Risks:

Metal chips, shards or particles coming from tools, etc.

The mechanical risks are defined as shocks, flying chips or solid particles.

To choose between safety glasses, safety goggles and safety face shields, the type and extent of the risk must be known:

• for a turning operation, safety glasses may be sufficient.

• for cutting work, a face screen is essential to protect the eyes and face.

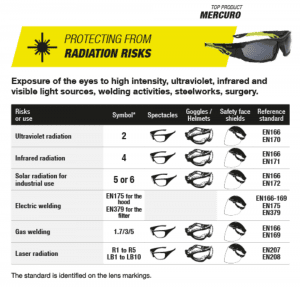

RADIATION — Optical radiation is present in many activities in industrial, medical or commercial fields.

Welding flash, steelworks laser, UV radiation from the sun and surgical processes are all concerned.

Over-exposure of the eyes to high-intensity sources can cause burns and lesions of the eye.

Bollé Safety has developed safety glasses, safety goggles, safety face shields and welding helmets to protect against optical radiation.

Practical examples of optical radiation:

Invisible UV radiation, visible and invisible IR radiation, etc.

The risks linked to radiation are defined as ultraviolet, infrared, visible light, gas welding, electrical welding, laser.

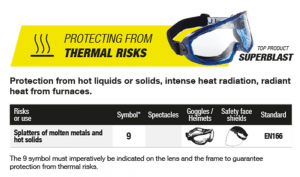

TEMPERATURE (THERMAL RISK) — Pay attention to dangerous levels of heat.

The thermal risk occurs when liquids or hot solids are splashed or intense radiation is emitted.

Bollé Safety has developed safety glasses, which comply with current standards, for protection against thermal risks.

Practical examples of Thermal Risk:

Radiant heat coming from ovens, splashes of molten metal or hot solids, furnaces/open flame and intense heat radiation.

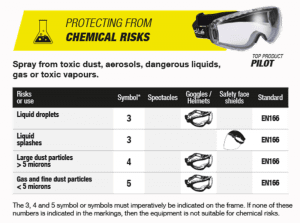

CHEMICAL — The chemical risk occurs when a substance projected or present in the environment reacts with the components of the eye or the skin and it appears in most industrial sectors.

This risk is particularly present in the medical field, the agri-food industry or in waste management, where micro-organisms are likely to contaminate individuals.

To prevent any risk of chemical splashes, Bollé Safety offers a wide range of safety goggles for protection against chemical and biological risks.

Practical examples:

Dust, aerosols, hazardous liquids, powders, gas or vapours.

Chemical risks are defined as projections of hazardous liquids, toxic dust, gas, toxic vapours.

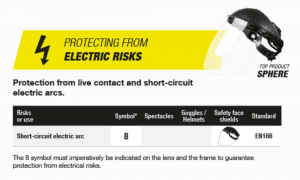

Electric Risk – Eye protection against short-circuit electric arcs must be safety face shields only. It must not have exposed metal parts and all the outer edges of the protection must be rounded, chamfered or otherwise treated so that there are no sharp edges.

The consequences of electric shock can be cornea burns, retinal lesions and conjunctivitis.

Practical examples:

Arc eye, electric arcs

WAVELENGTHS – Wavelengths are the basis of how we perceive the world around us and two organs enable us to receive them – eyes for light and ears for sound.

Gamma rays: very dangerous and can permeate cement and even lead. They destroy cells in living organisms.

X-rays: on the other hand, can also go through our body’s tissue but are stopped by our bones – this is why radiography is possible.

Ultraviolet rays: which come from the sun, are partially blocked by the ozone layer surrounding the Earth. Those that pass through that delight sunbathers but over-exposure can be very damaging.

Infrared rays: are emitted by all warm objects. These rays are not visible but their heat can be detected.

Radio waves: are used to transmit sounds, images and digital data. The human eye is not able to identify the various elements of a ray – it only sees the result. It can only see wavelengths that measure between 380 and 780 nanometres – this is known as the ‘visible spectrum’.

FRAMES

FRAME MARKINGS – SAFETY CODES

To help those workers get the correct safety glasses and goggles for the job they are doing the EN Specification system provides all the information needed.

The frame code will include 3 elements that will vary in order depending on the manufacturer, but never in meaning – the manufacturer´s name, strength designation and style designation are the 3 elements. Our team of professionally trained staff will offer advice on choosing the appropriate lenses for the job, however, here are some guideline on the Safety Codes used in safety goggles:

Strength Designation:

- S – 12 meters per second small object impact rating.

- F – 45 meters per second small object impact rating.

- B – 120 meters per second small object impact rating.

- A – 190 meters per second small object impact rating.

- T – Can be used in extreme temperatures.

Style and Protection of Frame Codes:

- 3 – Liquid splash protection (usually sealed goggles).

- 4 – Dust protection over 5 microns.

- 5 – Dust protection under 5 micros.

- 9 – Resistant to the penetration of hot solids.

FRAME AESTHETICS

Your safety eyewear’s frame & lens options are an essential consideration. As well as these, comfort and functionality should also influence your purchase decision. Remember, whether you’re purchasing eyewear for yourself or employees, people want to wear safety eyewear that looks good, is comfortable and is easy to use. If your eyewear looks terrible and is uncomfortable, the chances of not wearing it goes up dramatically. Nobody wants to wear a pair of uncomfortable safety glasses for hours on end. Look for eyewear that’s lightweight and has been designed ergonomically to be comfortably worn for extended periods. Look for styles with extra comfort features, such as soft nosepieces, rubber temples, and ergonomic frames. You can also find styles with different frame sizes to accommodate users with small or large faces.

LENS INFORMATION

LENS SAFETY MARKINGS

The indicators of eye protection afforded by the lens are found in the four elements etched on the lens, without including the fifth element – the manufacturer. The order of this code presented usually follows Radiation Protection, Light Transmission, Optical Quality, and Lens Properties.

Radiation Protection:

- 2 – UV protection (EN170) coloured filter.

- 2C or 3 – UV protection (EN170) with a clear filter.

- 4 – IR filters (EN171).

- 5 – Sun glare protection (EN172)

- 6 – Sun glare with IR filter (EN172 + EN171)

Light Transmission:

- 2 – Allows between 74.4% and 100% of light to pass.

- 7 – Allows between 43.2% and 58.1% of light to pass.

- 5 – Allows between 17.8% and 29.1% of light to pass.

- 1 – Allows between 8% and 17.8% of light to pass.

Optical Quality:

- 1 – Class 1 – High quality for regular use.

- 2 – Class 2 – Medium quality for occasional use.

- 3 – Class 3 – Low quality for exceptional use.

Lens Properties:

- F – Protect against small object impacts of 45 meters per second.

- B – Protect against small object impacts of 120 meters per second.

- A – Protect against small object impacts of 190 meters per second.

- T – Withstands extreme temperatures.

- N – Anti-fog

- K – Resistant to damage from fine particles.

- 9 – Resistance to the penetration of hot solids.

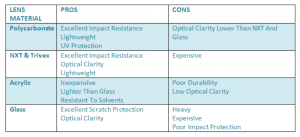

LENS MATERIALS

- Lens Coatings — Lens coatings are used to improve the functionality of safety glasses. Anti-fog coatings are one of the most popular as they reduce or eliminate lens fogging. Other standard options are a hard coat, hydrophobic, anti-reflective, blue light blocking, and mirrored coatings.

- Lens Tints — Lens colour is a critical consideration for safety eyewear. For indoor and low-light environments, clear lenses are the most common. Shaded lenses are typically used outdoors to protect from bright sunlight. While speciality lens tints are available for special hazards or light conditions, such as weld flash or arc flash protection.

Purchasing safety glasses doesn’t have to be confusing. Using this guide will ensure you’re making the proper considerations before spending your hard-earned money.

To contact us for more information, click here.